The group specializes in microstructure formation in materials (thermodynamics and kinetics of phase transformations) and develops new methods that employ temperature and concentration gradients for materials characterization and design. One focus is on the development and improvement of alloys used in optics.

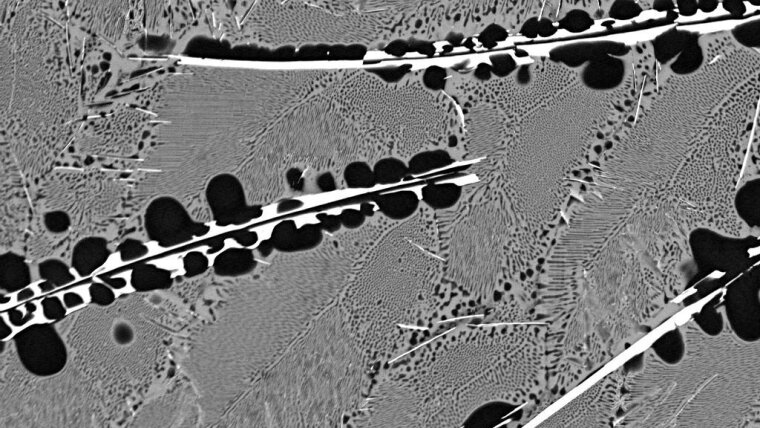

- Phase selection and solidification behavior (Al alloys, metallic glass former)

- Rapid transformations in solids (Cu and Ti alloys)

- Development of solder and brazing materials (Ag based, Cu based, Fe based)

- Alloy development for additive manufacturing (light weight alloys, hardfacing alloys)

The Group has expertise in the field of computer-assisted applied thermodynamics (CALPHAD method) as well as electron microscopy and spectroscopy.

-

Methods

Gradient methods for materials characterization are available

for studying phase transformations:

- early stages of melting (incl. nucleation rates)

- solid/liquid phase dynamics

- thermodynamic state of migrating interfaces

- competition of solid-state reactions

for materials constitution:

- determination of solidus and liquidus lines/surfaces

- determination of solvus lines/surfaces

- synthesis of pure intermetallic phases (cp)

for kinetics, thermophysical properties:

- T-dependent chemical diffusivities

- solid/liquid interfacial energies of alloys

- T-dependent thermal properties (diffusivity and conductivity)

-

Equipment

- Electromagnetic levitator (EML) for containerless processing

- Device for controlled pulse heating with electric current

- High- and middle-frequency induction furnaces

- Bulk-sample directional solidification setups with forced and reduced convection

- High speed infrared camera ImageIR 8380hp with area detector

- Transmission electron microscope JEOL NEOARM 200Fpdf, 3 mb (funded by DFG Inst 275/391-1); Terms of usepdf, 2 mb · de

-

Thesis

We offer Bachelor/Master theses and other student research work for materials scientists, chemists and physicists. The topics are closely related to our research activities and frequently in collaboration with other research groups or industrial partners.

The subjects listed below are meant to give an orientation about the research possibilities. The list does not provide all-ready picks. In a personal conversation with Dr. Stephanie Lippmann personal preferences should be identified and included in the planned research work.

- Studying the competition of solid-state reactions in Ag based alloys

- Directional melting of incongruently melting intermetallics

- Measuring thermal properties of graded alloys

- Developing a brazing alloy for joining SiSiC in the temperature range between 250 and 400°C

- Experimental investigation of false bottom formation with metallic model alloys in application to climate change

- Investigating phase selection of Cu-Zr based bulk metallic glasses in rapid solidification